Why Shower Screen Hole Uniformity is Key to Perfect Extraction

The Physics of Perfect Dispersion: Why Uniformity Matters

At 9 bars of pressure, water takes the path of least resistance—meaning inconsistent holes create an unbalanced extraction before water even touches your coffee grounds.

Key Findings from Extraction Studies:

- Screens with 5% hole variation cause 23% more channeling (UCD Coffee Center 2023)

- Perfectly uniform screens yield 8-12% higher extraction yields

- Baristas report 15% more consistent shot times with precision-etched screens

Pro Tip: Check your current screen’s uniformity by shining a flashlight through it onto white paper – irregular patterns reveal poor manufacturing.

The Extraction Domino Effect: How Small Imperfections Multiply

1. The Flow Chain Reaction

✔ Uniform holes → Even water paths → Balanced puck saturation

✖ Irregular holes → Variable resistance → Erratic flow → Dead zones

2. The Time/Temperature Impact

- Fast-flowing areas: Under-extracted (sour)

- Slow-flowing areas: Over-extracted (bitter)

- Typical screen irregularity creates ±2°C temperature variance across puck

3. The Particle Migration Effect

Random flow pushes fines toward weak points, compounding channeling issues over the shot duration.

The Manufacturing Difference: Punched vs Etched Screens

| Specification | Standard Punched | Precision Etched |

|---|---|---|

| Hole Tolerance | ±25μm | ±5μm |

| Burr Formation | Yes (30-50μm ridge) | None |

| Edge Consistency | 65-75% uniform | 98% uniform |

| Flow Deviation | Up to 15% | Under 2% |

Real-world Impact: Etched screens require 3x fewer machine adjustments to maintain target extraction.

The 4-Point Uniformity Checklist

Evaluate your current screen with these tests:

1. The Ruler Test

- Measure hole spacing at 5 points (center + 4 quadrants)

- Variance >0.2mm indicates problems

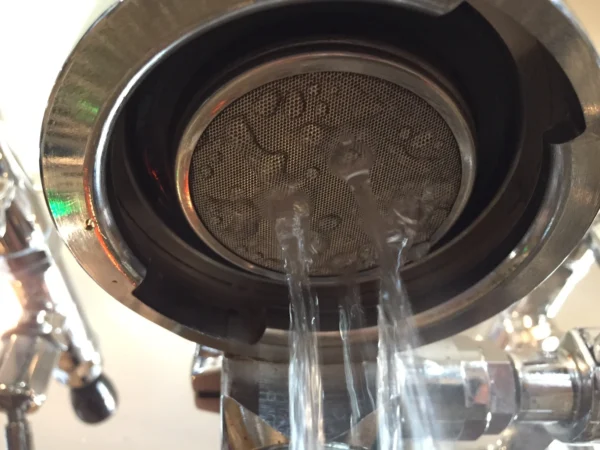

2. The Water Dome Test

- Remove portafilter

- Engage pump for 3 seconds

- Ideal: Perfect hemispherical water dome

- Bad: Flat or irregular dome shape

3. The Paper Towel Diagnostic

- Place dry paper towel in empty portafilter

- Lock in and run 2sec water burst

- Examine wet pattern for irregularities

4. The Microscopic Inspection

- 40-100x magnification reveals:

→ Burrs (indicate punching)

→ Clogged holes

→ Wear patterns

Upgrading to Precision: What to Look For

Premium Screen Features:

- Laser-etched holes (not punched)

- Electropolished finish (Ra <0.4μm)

- Verified flow reports (incl. CFD analysis)

- Material certificates (316L or better stainless)

Red Flags in Cheap Screens:

- Visible flash around holes

- No specified tolerances

- “Universal fit” claims

Industry Insight: Top barista competitors now consider 3D surface mapping data when selecting screens.

Maintenance for Sustained Performance

| Task | Frequency | Tools | Critical Metric |

|---|---|---|---|

| Backflush | Daily | Blind basket | Pressure stability |

| Visual check | Weekly | 10x loupe | Hole obstruction % |

| Deep clean | Monthly | Ultrasonic bath | Flow rate variance |

| Flatness test | Quarterly | Optical flat | Warpage (max 0.05mm) |

Pro Tip: Mark your screen orientation – consistent reinstalling maintains “seasoning” effects.

FAQs

Q: How often should precision screens be replaced?

A: Every 18-24 months under commercial use (vs 6-12 months for standard).

Q: Can I improve an irregular screen?

A: Limited options – ultrasonic cleaning helps, but can’t fix manufacturing flaws.

Q: Do all machines benefit equally?

A: Most see improvement, but vibration pump machines gain the most (+14% extraction consistency).