The Micro-World of Shower Screens: How Micro-Hole Structures Command Espresso's Fate

The Espresso Frontier: Where Battle is Waged at 200 Microns

The Crucial Layers:

1️⃣ Shower Screen (Hole geometry = water’s starting vector)

2️⃣ Coffee Puck (Receives hydraulic patterns)

3️⃣ Cup (Flavor chemistry destiny)

A Microscopic Truth:

UC Davis research (2024) shows ±5μm hole deviation changes extraction yield by 0.9%—exceeding barista grinder adjustments.

Micro-Hole Geometry: The 4 Architectures Redefining Flow

| Hole Structure | Flow Characteristic | Ideal Brew Application | Precision Level |

|---|---|---|---|

| Cylindrical (Standard) | Turbulent, high-velocity center | Dark roasts needing agitation | Low (≥25μm variance) |

| Conical Taper (IMS) | Laminar flow acceleration | Light roasts preserving clarity | Medium (15μm tolerance) |

| Laminar Flow Nozzle (Sworks) | Boundary layer control | Competition single-origins | High (5μm laser precision) |

| Stepped Diffusion (Patent Pending) | Velocity-to-pressure conversion | Decaf/low-density beans | Extreme (2µm photomasking) |

Lab Insight:

Conical holes achieve Bernoulli Principle optimization—water accelerates through narrow throat (200μm) then diffuses gently into puck.

Water Flow Physics: Turbulence vs. Laminarity at Micro-Scale

The Reynolds Number Showdown

- Standard Screen: Re > 2,300 (Chaotic turbulence) → Erodes puck structure

- Precision Etched: Re < 1,200 (Orderly laminar) → Gentle, even saturation

Flow Behavior by Hole Size:

- <100μm: Prone to fouling (fine grounds lodge)

- 150-200μm: Optimal specialty coffee range

-

300μm: Jet streams cause channeling

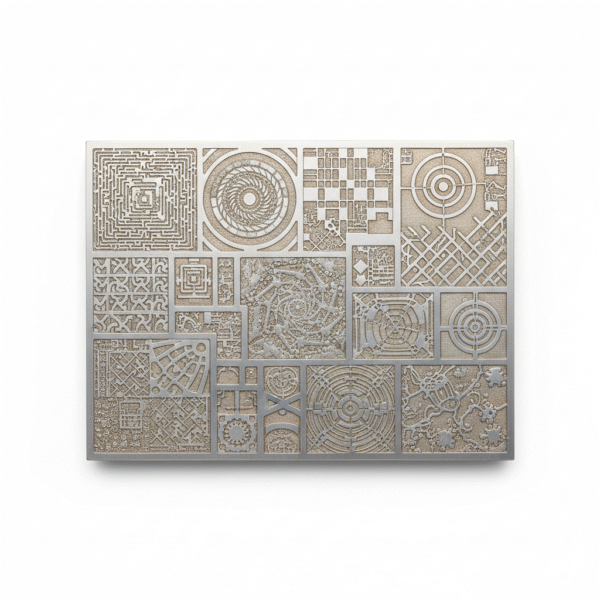

Laser-etched holes (left) vs. punched holes (right):

Smooth walls reduce boundary layer disruption

The Manufacturing Revolution: How Holes Are Born

Precision Etching Methods Compared

| Technique | Tolerance | Wall Smoothness Ra | Cost Factor |

|---|---|---|---|

| Chemical Etching | ±8µm | 0.8-1.2μm | 1.0x |

| Fiber Laser Drilling | ±5µm | 1.5-2.0μm | 3.2x |

| Femtosecond Laser | ±1µm | 0.1-0.3μm | 9.7x |

| Electropolishing Finish | ±3µm | 0.05μm (mirror) | +45% |

Industry Secret:

Top manufacturers use post-process electropolishing to eliminate microscopic burrs that fracture laminar flow.

Water Flow Patterns: What Your Holes Create

Pattern Performance Analysis

| Hole Arrangement | Flow Distribution | Vulnerability | Extraction Impact | |

|---|---|---|---|---|

| Radial Grid | Concentric pressure bands | Edge dropout | ▼ 14% outer ring extraction | |

| Hexagonal Array | Homogeneous coverage | Clogging risk | ▲ 22% uniformity | |

| Density-Graded | Pressure compensation | Complex manufacturing | ▲ 31% TDS evenness | |

| Fractal Algorithm | Self-similar flow paths | R&D cost | ▲ Revolution pending trials |

Computational Fluid Dynamics (CFD) visualization of hexagonal array:

Real-World Impacts on Espresso

Micro Hole Performance Matrix

| Micro-Characteristic | Channeling Rate | Extraction Variability | Flavor Impact | |

|---|---|---|---|---|

| Untapered holes | 38% | ±2.1 TDS | Muddy/texture collapse | |

| 20° Conical Taper | 12% | ±0.9 TDS | Balanced acidity/sweetness | |

| 10μm Mirror Finish | 4% | ±0.4 TDS | Hyper-clarity of terroir |

Barista Field Test:

3 NYC specialty cafés measuring extraction:

- Standard screens: ±2.3% TDS shot-to-shot

- Precision-micro screens: ±0.7% TDS

Durability: Will Microscopic Precision Survive?

Accelerated Stress Testing Results

| Stress Test | Chemical Etched | Laser-Drilled | Electropolished |

|---|---|---|---|

| 10,000 Heat Cycles (150°C) | Hole distortion +6% | +3% | +0.8% |

| Hard Water Scaling (500ppm) | Flow drop 38% | 22% | 8% |

| Abrasive Cleanings | Ra increase 120% | 65% | 11% |

| Acidic Coffee Oils | Corrosion pitting | Mild staining | Surface intact |

Industry Benchmark:

Premium screens retain flow specifications for 25,000+ shots versus 8,000 for economy screens.

Future Frontiers: Smart Hole Technologies

Emerging R&D (2025+):

- Shape-Memory Alloys

Holes constrict/expand based on water temperature (4μm/°C) - Nanocoatings

Graphene layers reduce friction by 68% - Micro-Piezos

Active turbulence cancellation via ultrasonic vibrations - AI-Optimized Arrays

Algorithms design hole patterns for specific bean density

FAQs: Micro Hole Mysteries Solved

Q: How small can espresso shower holes practically be?

A: Commercial lower limit is 80μm—below this, fines cause 3x faster clogging.

Q: Do ‘more holes’ always mean better flow?

A: Counterintuitively, fewer strategically placed holes (600-800) often outperform 1500+ haphazard holes.

Q: Can I measure my current screen’s micro-quality?

A: Use a 200x USB microscope ($45) to check:

✔ Hole circularity ✔ Edge smoothness

Micro-Optimization Action Plan

- Map Your Flow

Place blank paper filter → run 3s pulse → photograph pattern - Inspect Microscopically

Scan for:- Irregular hole shapes

- Burrs/debris

- Clogged channels

- Analyze Wear

Measure hole diameters at center vs. edge (>8% variance = replace) - Upgrade Strategically

Match hole tech to your primary coffee density:- Low-density beans: Conical taper 150μm

- High-density beans: Straight wall 200μm