REACH Regulation: Ensuring Chemical Safety for Stainless Steel Components

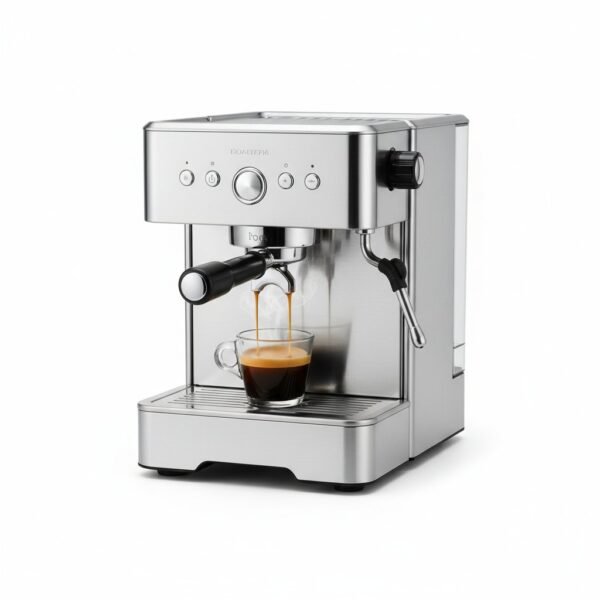

The EU’s REACH Regulation (EC 1907/2006) governs chemical safety for all products sold in Europe—including stainless steel espresso components like puck screens and portafilters. For importers and manufacturers, REACH compliance isn’t optional—it’s legally mandatory.

This guide explains:

✔️ What REACH means for stainless steel coffee parts

✔️ Key substances of concern (Nickel, Chromium VI, etc.)

✔️ How Caffepress guarantees full compliance

✔️ Documentation you’ll need for customs clearance

Why REACH Matters for Coffee Equipment

1. REACH in Simple Terms

- Applies to all imported goods containing chemicals (even metals)

- Restricts 211 Substances of Very High Concern (SVHCs)

- Requires supplier documentation for customs

2. Stainless Steel-Specific Risks

While stainless steel (304/316L) is inherently stable, REACH monitors:

⚠️ Nickel (Ni) migration (allergenic potential)

⚠️ Hexavalent Chromium (Cr VI) (carcinogenic if improperly processed)

Case Example: In 2022, a German distributor faced €28k fines for non-compliant shower screens with unverified passivation.

3. Food Contact Materials (FCM) Overlaps

REACH interacts with:

- EU 1935/2004 (General food contact safety)

- Germany’s LFGB (Strict heavy metal tests)

How We Ensure Compliance at Every Step

1. Material Sourcing Controls

✔️ Only EU-registered stainless steel mills

✔️ Batch-tested for SVHCs below 0.1% w/w

✔️ Full IMDS (International Material Data System) sheets

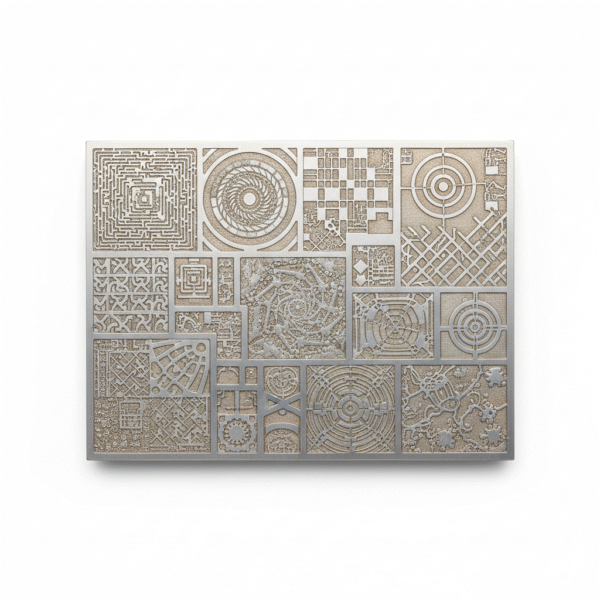

2. REACH-Certified Manufacturing

| Process | Risk | Our Solution |

|---|---|---|

| Chemical Etching | Acid residues | Neutralization baths + triple rinsing |

| Passivation | Cr VI formation | Citric acid passivation (REACH-approved) |

| Laser Engraving | Fumes | HEPA filtration systems |

3. Lab Testing & Documentation

Every shipment includes:

- REACH Declaration of Conformity

- Migration test reports (EN 1186 series)

- Material composition certificates

Key Documentation for Importers

- Supplier’s REACH Compliance Letter (Proves SVHCs < threshold)

- DoC referencing EU 1907/2006

- Test Reports Showing:

- Nickel release < 0.12 µg/cm²/week (EN 1811)

- No detectable Cr VI (ISO 3613)

Pro Tip: Keep these digitally—EU customs requests them for 10+ years post-import.

Special Considerations for Coffee Parts

1. Higher Scrutiny for Wet-Contact Components

Puck screens and shower screens face stricter tests because they:

- Have prolonged water/coffee oil exposure

- Experience thermal cycling (accelerates leaching risks)

2. The “Article” vs. “Mixture” Distinction

- Stainless steel puck screens = Articles (Compliance focuses on material)

- Packs with cleaning tablets = Mixtures (Additional SDS requirements)

Non-Compliance Consequences

| Scenario | Risk |

|---|---|

| Missing DoC | Customs seizure + 5% product value fine |

| SVHC exceedance | Recall + €50k+ penalties |

| False claims | Blacklisting from EU markets |

How to Verify Your Supplier’s Compliance

Ask these 5 questions:

- “Can you provide a REACH DoC for this alloy?”

- “What’s your Cr VI prevention method?” (Correct answer: Citric or nitric passivation)

- “Do you test nickel migration per EN 1811?”

- “Are your raw material suppliers on the EU REACH registry?”

- “Can we audit your test reports?”

🚩 Red Flag: Suppliers who call stainless steel “100% REACH exempt”—all metals require documentation.

FAQ

Q: Does REACH apply to non-EU B2B sales?

A: Only if the end product enters the EU—but many global buyers now demand it.

Q: How often should materials be retested?

A: Annually, or after any process change (e.g., new etching chemicals).

Q: Can we self-certify REACH compliance?

A: No—only test reports from accredited labs (e.g., SGS, TÜV) are accepted.

Conclusion & Next Steps

REACH compliance protects your business from:

✅ Customs delays

✅ Product recalls

✅ Legal liability

Caffepress guarantees:

- Full REACH documentation with every order

- Pre-shipment lab testing upon request

- Continuous monitoring of regulation updates