Heavy Metal Testing for Stainless Steel Shower Screens: Ensuring Non-Toxic Safety

Heavy Metal Testing for Stainless Steel Shower Screens: Ensuring Non-Toxic Safety

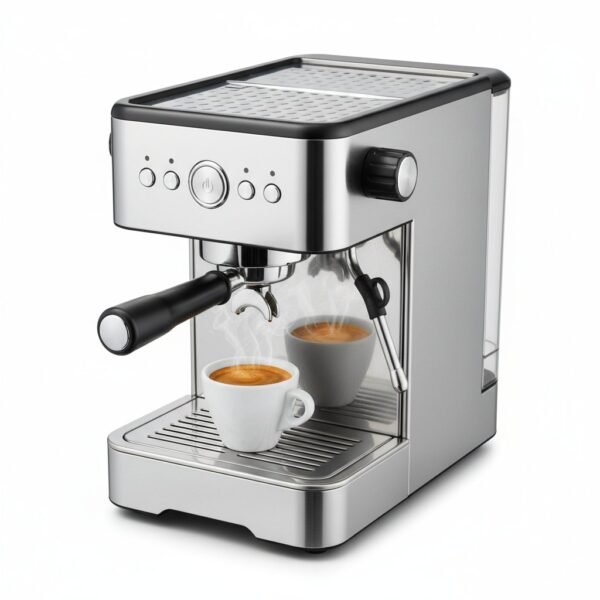

As distributors and OEM brands of shower screens, you understand the critical importance of product safety and quality. Your customers demand assurance that the products they purchase are not only aesthetically pleasing and functional but also free from harmful substances. This article delves into the crucial role of heavy metal testing in stainless steel shower screens, providing a comprehensive overview of why it’s essential, what it entails, and how it benefits your business.

Why Heavy Metal Testing Matters for Shower Screens

Stainless steel is widely favored for shower screens due to its durability, corrosion resistance, and aesthetic appeal. However, even high-grade stainless steel can contain trace amounts of heavy metals like lead (Pb), cadmium (Cd), mercury (Hg), hexavalent chromium (Cr(VI)), and arsenic (As). While these metals may be present in minimal quantities, their potential to leach into water, especially under acidic or high-temperature conditions, poses a significant health risk. Chronic exposure to even low levels of these heavy metals can lead to various health problems, including:

- Neurological damage: Lead, mercury, and arsenic are neurotoxins that can impair brain development and cognitive function, particularly in children.

- Kidney damage: Cadmium is known to accumulate in the kidneys and cause kidney disease.

- Cancer: Hexavalent chromium is a known carcinogen and can increase the risk of lung cancer.

- Developmental problems: Heavy metals can interfere with fetal development and cause birth defects.

Therefore, heavy metal testing is paramount to ensure that your shower screens meet stringent safety standards and protect consumers from potential health hazards. This proactive approach not only safeguards public health but also enhances your brand reputation and minimizes potential legal liabilities.

Understanding Heavy Metal Testing Methodologies

Several internationally recognized testing methodologies are employed to detect and quantify the presence of heavy metals in stainless steel shower screens. The specific method chosen depends on the target metals, the material being tested, and the required level of sensitivity. Here are some commonly used techniques:

Inductively Coupled Plasma Mass Spectrometry (ICP-MS)

ICP-MS is a highly sensitive analytical technique that can detect trace amounts of multiple elements simultaneously. The sample is first dissolved in acid, then introduced into an inductively coupled plasma, which ionizes the elements. The ions are then separated based on their mass-to-charge ratio and detected by a mass spectrometer. ICP-MS is particularly effective for detecting heavy metals in complex matrices like stainless steel and is widely used for regulatory compliance testing.

Atomic Absorption Spectroscopy (AAS)

AAS is another widely used technique for heavy metal analysis. In AAS, a sample is vaporized and illuminated with a specific wavelength of light. The amount of light absorbed by the sample is proportional to the concentration of the target element. AAS is a relatively simple and cost-effective technique, but it is less sensitive than ICP-MS and typically requires separate analyses for each element.

X-ray Fluorescence (XRF) Spectrometry

XRF is a non-destructive technique that can be used to determine the elemental composition of a sample without dissolving it. The sample is irradiated with X-rays, which causes the elements in the sample to emit characteristic X-rays. The energy and intensity of these X-rays are used to identify and quantify the elements present. XRF is particularly useful for screening large numbers of samples quickly, but it may not be as sensitive as ICP-MS or AAS for detecting trace amounts of heavy metals.

Regulatory Standards and Compliance

Globally, various regulatory bodies have established stringent limits for heavy metal content in products that come into contact with drinking water, including shower screens. Adhering to these regulations is crucial for market access and maintaining consumer trust. Some key standards include:

- NSF/ANSI 372: This standard establishes the maximum allowable lead content in drinking water system components. Although primarily focused on lead, compliance often indicates adherence to broader heavy metal safety protocols.

- California Proposition 65 (Prop 65): This California law requires businesses to provide warnings about significant exposures to chemicals that cause cancer, birth defects, or other reproductive harm. While not a direct heavy metal standard, it necessitates testing for listed heavy metals if they are likely to be present in the product.

- European Union (EU) REACH Regulation: REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) restricts the use of certain hazardous substances, including heavy metals, in various products sold in the EU.

- Various national standards: Many countries have their own specific regulations for heavy metal content in plumbing products. You should ensure that your shower screens comply with the regulations of the target market.

Partnering with accredited testing laboratories that are familiar with these regulatory requirements is essential for ensuring compliance and avoiding potential penalties.

Benefits of Heavy Metal Testing for Your Business

Investing in heavy metal testing for your stainless steel shower screens offers several significant advantages:

- Enhanced product safety: It protects consumers from potential health risks associated with heavy metal exposure.

- Regulatory compliance: It ensures that your products meet all applicable regulatory requirements, facilitating market access.

- Improved brand reputation: It demonstrates your commitment to quality and safety, building consumer trust and loyalty.

- Reduced liability risks: It minimizes the risk of product recalls and lawsuits related to heavy metal contamination.

- Competitive advantage: It differentiates your products from competitors who may not be as rigorous in their quality control processes.

- Demonstrating corporate social responsibility: It aligns with the growing consumer demand for sustainable and ethically sourced products.

Choosing a Reliable Testing Partner

Selecting the right testing partner is crucial for obtaining accurate and reliable results. Look for laboratories that are:

- Accredited: Accreditation by a recognized body (e.g., ISO 17025) ensures that the laboratory meets international standards for competence and quality.

- Experienced: The laboratory should have extensive experience in testing stainless steel products for heavy metals.

- Equipped: The laboratory should have state-of-the-art equipment and experienced personnel to perform the required tests.

- Reputable: Check the laboratory’s reputation and track record through customer reviews and industry references.

- Transparent: The laboratory should be transparent about its testing methodologies, results, and pricing.

Summary

Heavy metal testing is an indispensable component of ensuring the safety and quality of stainless steel shower screens. By understanding the potential risks, implementing rigorous testing protocols, and partnering with reputable testing laboratories, distributors and OEM brands can safeguard consumers, enhance brand reputation, and achieve sustainable business growth. Embrace heavy metal testing as a key differentiator in a competitive market and demonstrate your unwavering commitment to providing safe and reliable products to your customers.