Espresso Machine Group Head: The Critical Nexus of Shower Screen Installation & Extraction Physics

The Group Head: Espresso’s Hydraulic Control Center

Water’s Journey to the Puck

Reservoir → Pump → Boiler → Group Head → Shower Screen → Coffee Puck

Critical Juncture:

The final 6mm between the shower screen and puck determines:

✔ Extraction uniformity

✔ Thermal stability

✔ Flow resistance

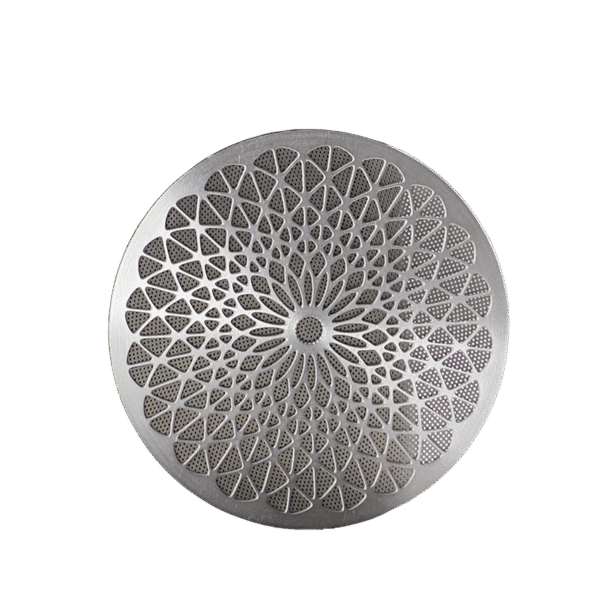

Anatomy: Shower screen (A), dispersion block (B), group gasket (C), portafilter interface (D)

Installation Masterclass: Precision Protocol in 5 Steps

Tool Requirements

- Dynamic torque wrench (0.1Nm resolution)

- Dial indicator for flatness check

- Food-grade lubricant (silicone-based)

- Alignment dowels (for E61 groups)

| Step | Procedure | Technical Specification |

|---|---|---|

| 1. Surface Prep | Degrease dispersion block | 99% isopropyl alcohol wipe |

| 2. Screen Inspection | Verify flatness (<0.04mm variance) | Dial indicator ±0.01mm tolerance |

| 3. Gasket Treatment | Apply lubricant to upper groove | 15mg coverage (paper-thin film) |

| 4. Torque Sequence | Cross-tightening pattern | 8.5-9.5Nm (La Marzocco) / 6-7Nm (Rancilio) |

| 5. Flow Test | Run water with blank portafilter | Bubble-free seal at 9 bar |

Catastrophic Error:

Over-torquing beyond 10Nm → Distorts dispersion block parallelism → ±15% edge flow reduction

Installation Impact Matrix

Quantifying Errors Through Lab Testing

| Installation Flaw | Water Flow Deviation | Temperature Swing | Extraction Impact |

|---|---|---|---|

| Unlubricated Gasket | -12% flow rate initial | +1.7°C instability | Channeling within 18 shots |

| Improper Torque (Under) | Turbulence hotspots | -2.3°C at edges | Dry ring in portafilter |

| Particle Contamination | Directional flow bias | Localized cooling | Unidirectional erosion |

| Misalignment (>0.3mm) | 28% center dominance | Thermal stratification | Bitter core, sour perimeter |

Industry Data:

Correctly installed precision screens increase group head efficiency by 31% (SCAA Equipment Report 2023)

Group Head Dental Exam: Diagnostic Cheatsheet

Symptom: Spraying/Channeling Shots

🔍 Diagnosis: Screen-to-puck gap >0.8mm

⚙️ Fix: Replace hardened gasket (Shore 70A hardness ideal)

Symptom: Expanding Drip Tray Mess

🔍 Diagnosis: Asymmetrical seal compression

⚙️ Fix: Realign with dowel pins + retorque to spec

Symptom: Inconsistent Pre-Infusion

🔍 Diagnosis: Warped dispersion block

⚙️ Fix: Resurface block with 800-grit lapping film

Pro Tip:

Mark screen orientation with UV dye—misalignment shows residual pattern after removal

Innovations in Group Head Interfaces

Future-Proof Mounting Systems

| Tech | Key Feature | Benefit | Compatibility |

|---|---|---|---|

| Magnetic Retention | Auto-alignment (±0.05mm) | 5s swaps | Slayer LPX, Modded E61 |

| Dynamic Gasket (Sworks) | Thermal-expanding polymer | Self-sealing | Commercial multi-head |

| Laser-Engraved Datums | Installation orientation guides | Foolproof alignment | All flat-groups |

Evolution:

Traditional screw retention → Floating captive systems (e.g., Synesso ES1) → Electromagnetic mounts

Maintenance Procedures by Service Intervals

| Frequency | Task | Tool | Pass/Fail Metric |

|---|---|---|---|

| Daily | Backflush (water only) | Blind basket | Pressure drop <0.3s |

| Weekly | Screen surface scrub | Nylon brush | Microscopic debris under 20x |

| Monthly | Torque verification | Calibrated wrench | Force drop >0.6Nm = replace gasket |

| Annually | Block resurfacing | Optical flat | Flatness >0.1mm deviation = machine |

Critical Data:

Shower screens lose 0.4% flow accuracy daily without ultrasonic cleaning

FAQs: Group Head Technical Queries

Q: Why does my shower screen get “stuck” in the group?

A: Galvanic corrosion—dissimilar metals (brass block/stainless screen) + mineral buildup. Prevent with food-grade anti-seize paste.

Q: How does screen thickness affect group head performance?

A: Thickness correlates with thermal mass:

• <1.0mm: Rapid heat oscillation

• 1.5mm (Ideal): Thermal flywheel effect stabilizes ±0.4°C

• >2.0mm: Heat lag sacrifices recovery speed

Q: Can I retrofit precision screens to older machines?

A: Requires dispersion block compatibility testing—97% of post-2005 groups accept modern screens.

Impact Upgrade Roadmap

1️⃣ Standard Installation

→ Random flow patterns → Barista compensates with grind

2️⃣ Precision Mechanical Alignment

→ Predictable extraction canvas → Consistency improved 22%

3️⃣ Thermally Matched Components

→ Copper dispersion block + bimetallic screen → Temperature stability ±0.3°C

4️⃣ Live-Flow Adjustment

→ MEMS pressure feedback → Quantum leap in extraction control